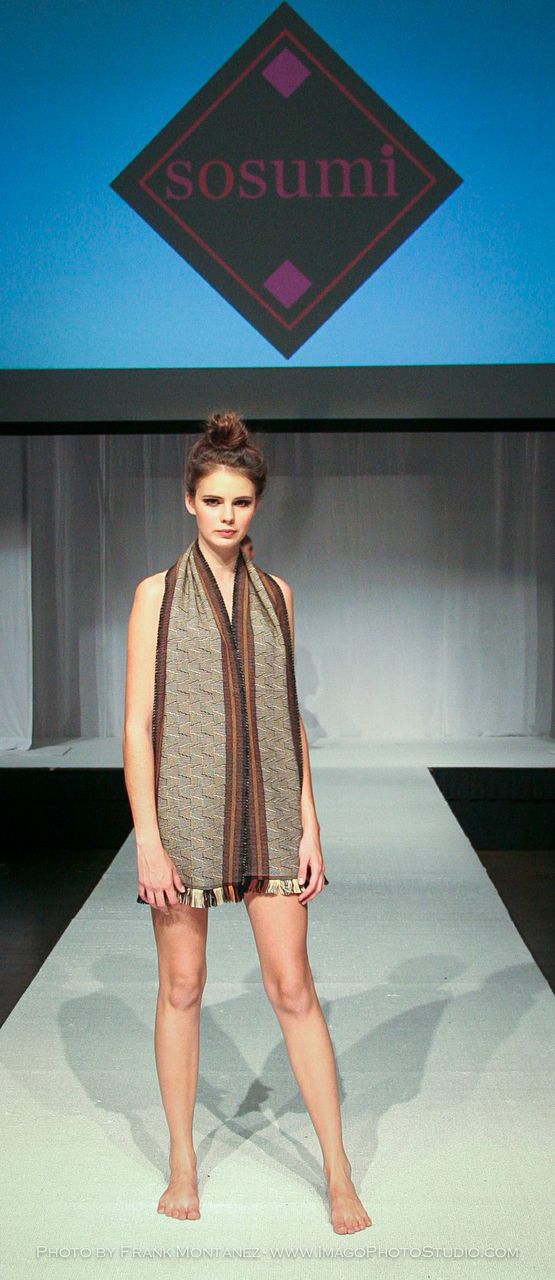

Sometimes life just gets busy, busy, busy. We have such a short window between the rush of Holiday orders and getting ready for the First Show of the Year. We basically have six weeks to come up with a new line for the new year. Yes, we do carry over patterns that everyone loves. Yes, we do carry over color combos that seem to work. But we always want to try new things, perhaps a totally new pattern or some wild and crazy color combination. Funny thing is that at the American Craft Council show a couple of weeks ago, when the show was open to the public (we had had two days of "to the trade only"), the wildest and craziest scarf went first. Bingo! (If you go onto the New Scarves 2016 page and scroll down to Deep V you will find one in Turquoise and Tangerine. Yep!)

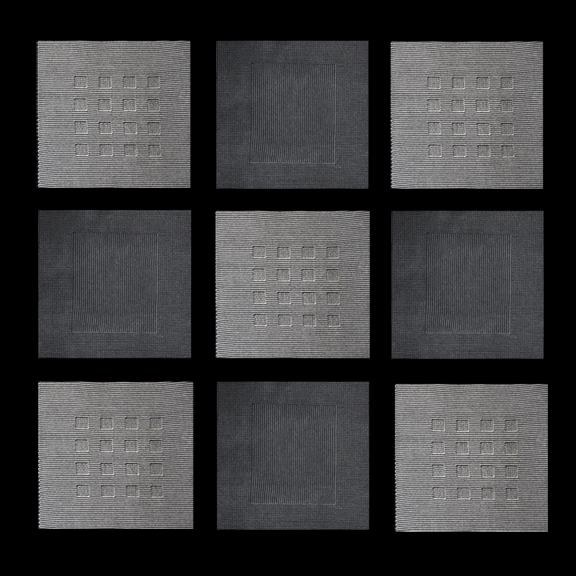

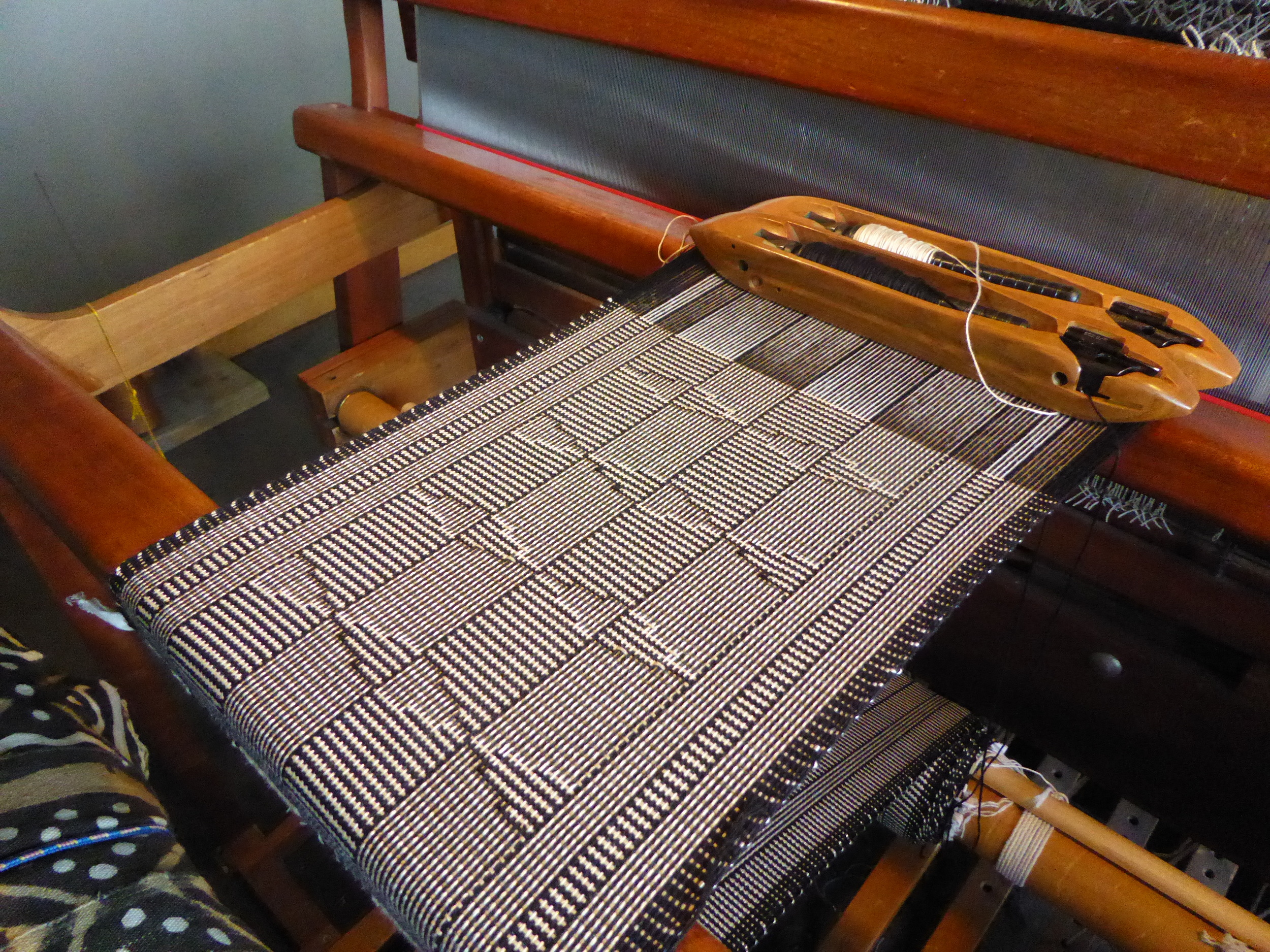

And besides getting ready for the show Richard received an order for a custom quilt (the design was called Wilder) for a client in Scottsdale,AZ. Just as he posted the series How To Make A Scarf, he plans to post an entry for How To Make A Quilt. Stay tuned as he now has an order for yet another custom quilt (this time a Crazy Quilt with a twist.)

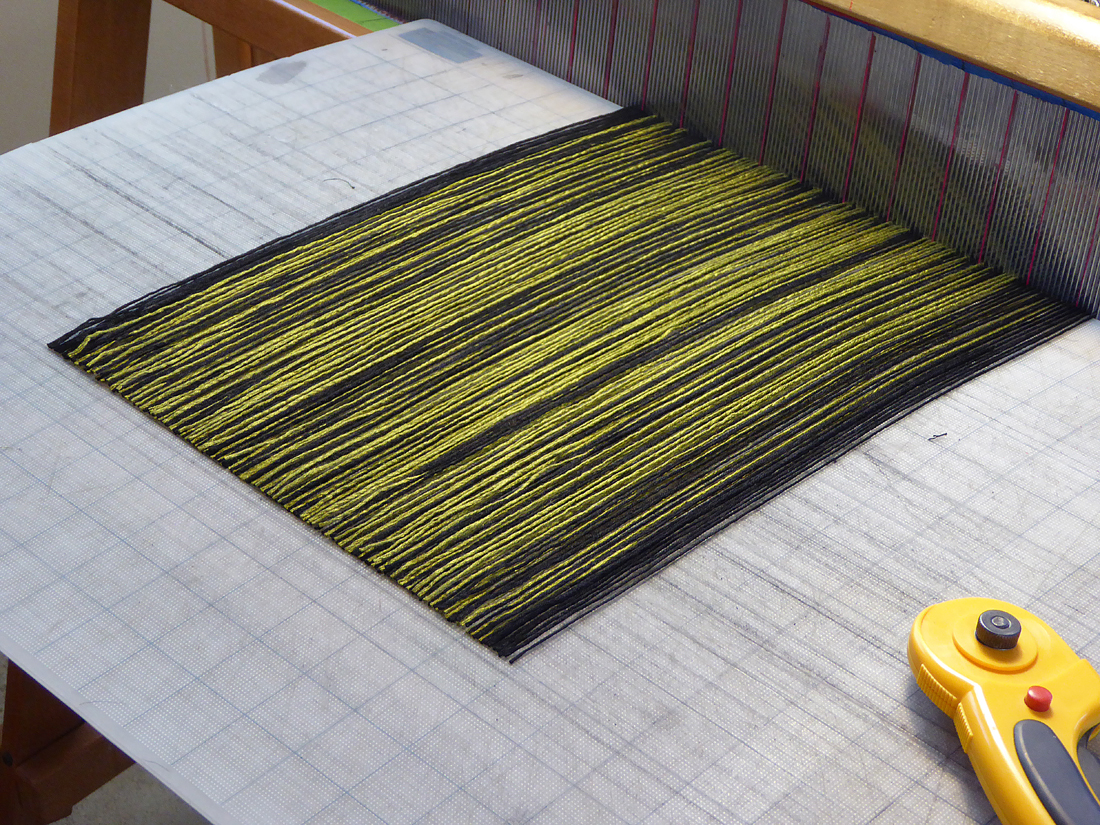

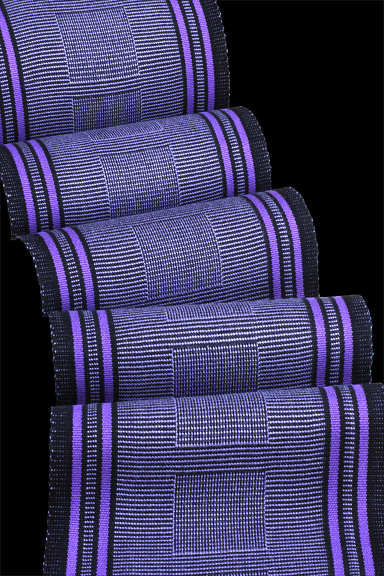

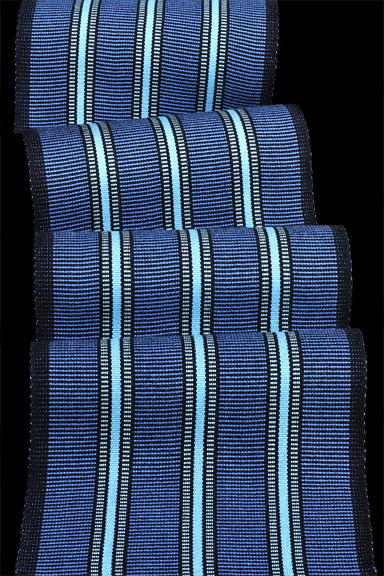

Scarf orders have been received with more coming in. Hoping for a great year. And if you are wondering what the above photo is....after the Africa scarves are woven the little tassels need to be trimmed. It made for a pretty composition.